We are with you all the way

Full partnership

Choosing a turnkey partner means having one expert take full ownership of your project, so you don’t have to coordinate multiple vendors or chase timelines.

.png)

Complete turnkey project

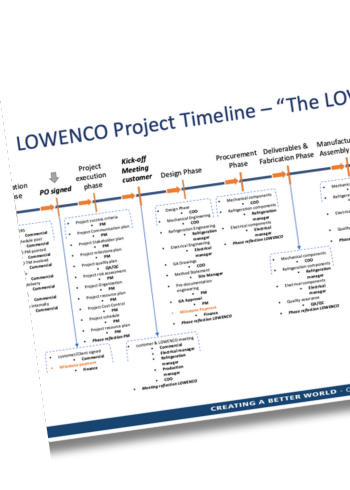

Get the complete LOWENCO project plan

- Detailed breakdown of each project phase

- Transparent pricing models and milestone-based payments

- Key compliance checkpoints

Choose the right delivery model for your ULT project

ULT storage projects involve many decisions, and one of the most important is choosing how the project will be delivered.

Some organizations are comfortable coordinating several suppliers, while others prefer a model where one partner is accountable for the entire scope.

Your choice should reflect your internal capacity, risk tolerance and the level of predictability you need during implementation.

The guide below is designed to help you assess which setup aligns with your resources and expectations.

Guide: Access the Best Partnership Structure

Traditional supplier structure

- Multiple vendors and subcontractors, which require constant coordination and follow-up across several parties

- Higher client involvement as planning, documentation and installation oversight must be managed internally

- Cost predictability can vary when scopes change or additional services are required

- Timelines may be affected if dependencies or responsibilities between suppliers are not fully aligned

- Inconsistent quality control as different suppliers follow their own standards and documentation practices

- The client coordinates all suppliers and holds responsibility if issues arise between vendors during execution

- With several parties involved, accountability is shared, which can make it harder to maintain a unified quality approach throughout the project

full service partnership

- One point of contact provides full project visibility, helping maintain oversight across all phases

- LOWENCO manages planning, permits, construction and installation, reducing the client’s operational workload

- Contracts offer a fixed price, supporting cost predictability throughout the project

- A streamlined delivery process and overlapping project stages are designed to support on-time execution

- LOWENCO takes responsibility for the full project scope, helping minimize delays and miscommunication associated with multi-party coordination

- Financial, technical and legal accountability is centralized with one partner

- Integrated procedures and unified quality practices help maintain consistent standards from start to finish

See products

.png)

Let's make your next cold storage project easier

Our turnkey experts can show you exactly how to simplify your project and reduce your workload.

.png)

.png)

.png)

.png)

%20(1).png)